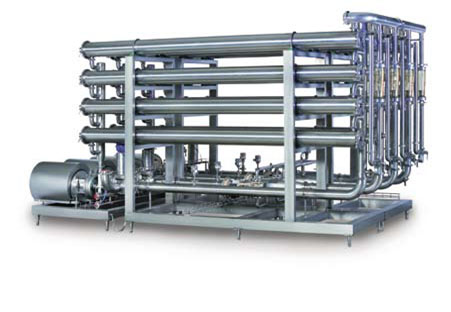

MF, UF, NF, RO SYSTEM

Model R Membrane Filtration Pilot Plant

The Model R membrane filtration pilot plant is a flexible unit

used to perform pilot studies on the full range of membrane

filtration technologies (MF, UF, NF and RO) under a wide

range of operating conditions.

The pilot plant’s standard configuration allows for testing

with spiral, polymeric membranes. It can also be set up with

other optional membrane configurations.

The pilot plant can be operated in batch mode, semi-batch

mode, or feed and bleed mode. The pilot plant design has a

single stage recirculation loop.

The Model R membrane filtration pilot plant is skid mounted

and will be delivered with all the components required for

quick installation and easy operation, including an operating

manual with data sheet templates.

Standard Features

. Two, sanitary, spiral membrane housings

- one membrane element per housing

- 3.8” diameter, sanitary design elements

. 15 gallon tank

. Control loops

- temperature

- tank level

- feed pump

- recirculation pump

. Motor starters

- variable speed drive for feed pump (5 Hp)

- variable speed drive for recirculation pump (7.5 Hp)

. Flow indicators

- two, permeate rotameters

- one, concentrate rotameter

- recirculation mag meter

. Pressure and temperature gauge

. Heat exchanger (0.5 m2)

. High pressure shut down and pressure relief valve

. 316L stainless steel construction

. Skid mounted with wheels

Operating Conditions

. Membrane Area

- Spiral 4 to 14 m2

- Ceramic 0.2 to 0.36 m2

- Stainless Steel 0.35 m2

. Permeate Capacity

- Spiral 20 - 50 gallons/hour

- Ceramic 5 - 50 gallons/hour

- Stainless Steel 10 - 50 gallons/hour

. Pressure up to 600 psig

. Temperature up to 200o F

Optional Features

. 1,000 psig capability

. Industrial, spiral membrane housings

. Other membrane configurations including tubular

polymeric, ceramic, and stainless steel modules

. Pretreatment equipment

- screens and depth filters

- chemical feed systems

. Back-pulse device in permeate piping

. Back-flush system in permeate piping

. Hazardous area or explosion-proof construction

등록된 코멘트가 없습니다.